Products

Rip Prevent

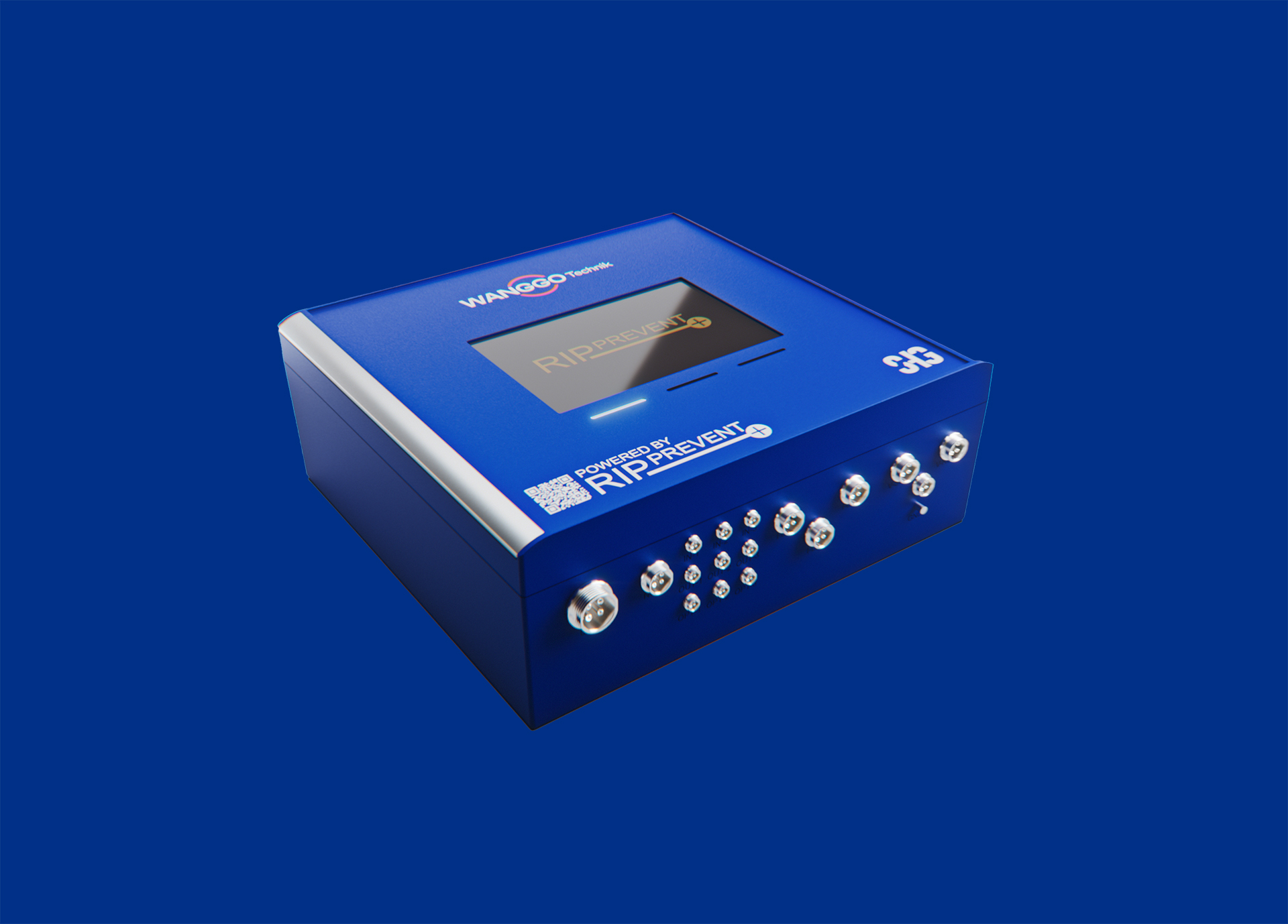

The revolutionary material handling monitoring system. Wanggo Advanced Maintenance offers operators of belt conveyor systems a new, highly efficient product. Thanks to a data-driven calculation model and the algorithm’s AI, faults, changes or damage are detected at an early stage. This can prevent cost-intensive downtimes. In addition, the productivity of conveyor systems can be increased by cleverly analyzing the data, which which in turn leads to a general increase in energy efficiency and and a reduction in operating costs.

Rip Prevent helps to permanently monitor the really important parameters of a belt conveyor system. A low monthly investment creates many advantages for operators.

Benefits at a glance

- Suitable for all conveyor belt types and constructions (textile, steelcord & special constructions)

- No sensor elements in the belt necessary

- Rip Prevent is wear-free

- Low investment costs

- Optimization of electricity costs

- Predictive maintenance in action

- Quick and easy installation

The right investment for your conveyor installation

- Slot detection and preventive slot detection

- Fault detection

- Motor monitoring

- Mass flow calculation

- Permanent condition monitoring

- Increasing energy efficiency

- Maintenance support

- Electrical network analysis

- Lifetime hardware warranty and monthly software updates

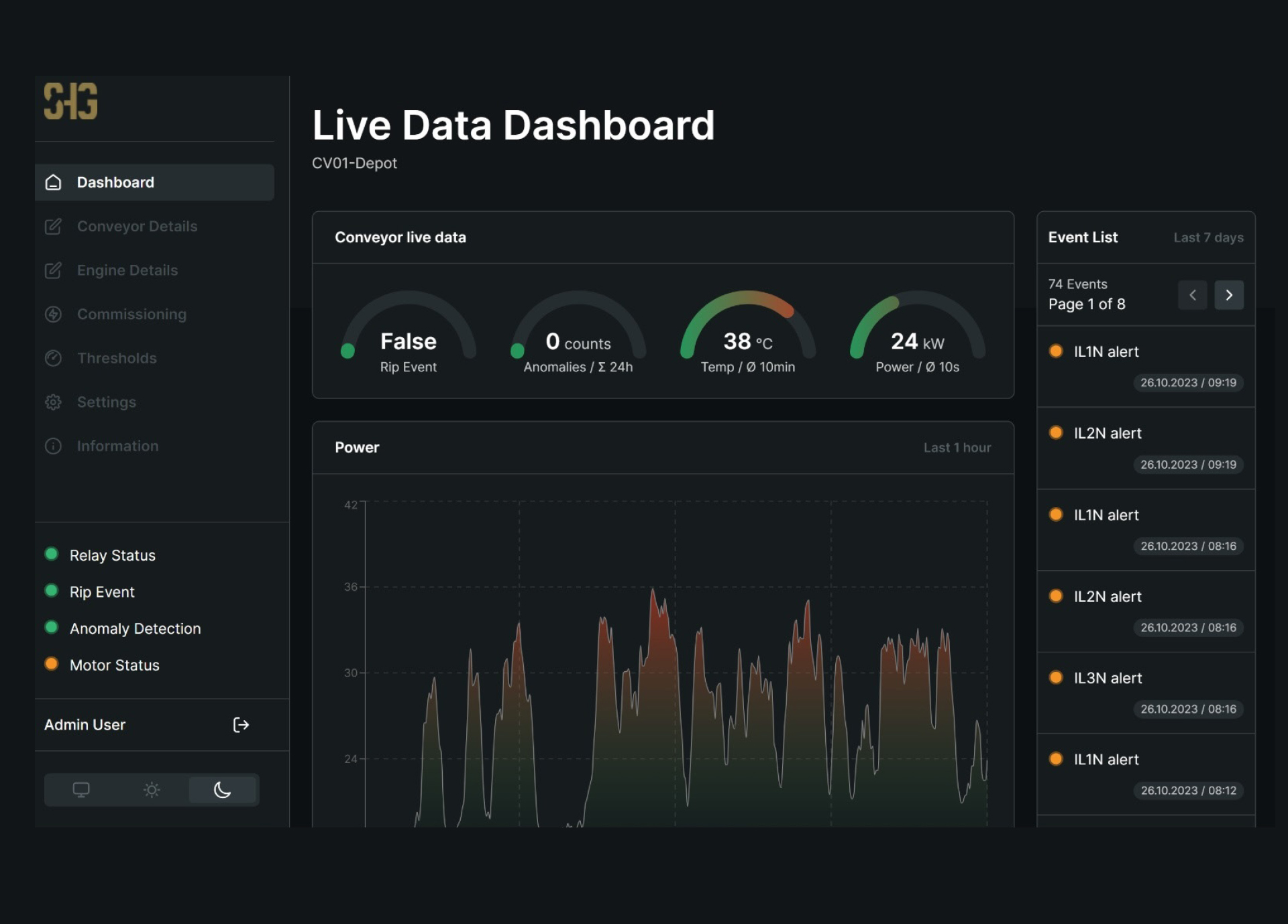

Key information on the dashboard

Crack detection indicates whether there is a crack event or a fault on the system. Utilization and productivity displays are the indicators for the efficiency of the conveyor system. The dashboard can be viewed on the 7″ display directly on the system or by integrating the system into the intranet via TCP/IP using the specific IP address in the web browser.

- Indicator for faults and cracks

- Relevant events (customizable for end users)

- Utilization and productivity of the system

- Motor status